Why Ipe Hardwood Is Perfect for the Pacific Northwest

If you live in the Pacific Northwest and you’re thinking about building a new deck this fall, you might be wondering if wood is the best choice given the region’s wet winters. As anyone in Portland or Seattle will tell you, constant rain can wreak havoc on wood structures. However, certain types of hardwoods – especially ipe – actually hold up quite well in rainy and wet climates. Let’s learn more!

Rain is no match for ipe

Ipe is an exceptional wood in many ways. Found in South and Central America, ipe trees (Brazilian Walnut) commonly grow to be 100 feet tall and 3 feet in diameter. There are three characteristics that make ipe perfect for outdoor decks in Portland and Seattle.

- Strong: Ipe is also exceptionally strong. Compressive strength measures how much a wood can handle parallel to its grain. For example, this indicates the weight the legs of a table could withstand before buckling. Ipe’s compressive strength is 13,600 lbf/in2, which is impressive especially when compared to cedar’s strength of 4,560 lbf/in2.

- Dense: Ipe is one of the most dense woods too, with a density of 69 lbs. per cubic foot. Why is this important? Density is a great indicator of wood strength: the denser the wood, the stronger it is. Dense woods are perfect for the Northwest because they handle water much better than soft, light woods. Its density also contributes to its natural rot and decay resistance.

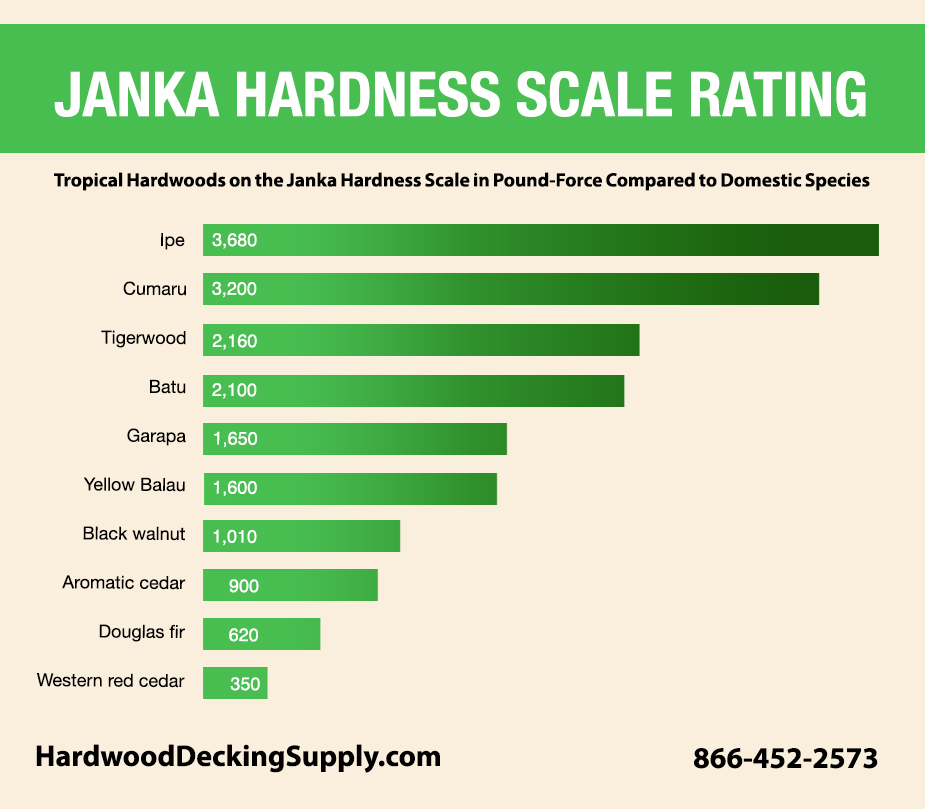

- Hard: With a Janka Hardness Rating of 3,680 lbs, ipe is one of the hardest woods you can find. Ipe is eight times harder than California redwood!

Why else is ipe wood superior?

Beyond the factors mentioned above, ipe doesn’t splinter, so it’s great to walk on with bare feet in the summer. It is also slip resistant, so you don’t have to worry about walking on in in the rain. Incredibly, ipe is resistant to fire, thanks to its density, so it’s a smart option if you live in a wildfire-prone area.

Factors to keep in mind

1) It’s important to properly store your ipe hardwood until you begin your project. While air dried ipe needs to be acclimated on-site before the project begins, all of Hardwood Decking Supply’s wood is kiln dried, so it’s ready to be used upon delivery. That being said, if you’re not using your wood immediately, make sure to store it off the ground and covered with a tarp to avoid exposure.

2) Ensure your project is properly ventilated to avoid warping or cupping. The surface of a deck should be 16 inches above the ground (or more when installed over water or wet areas) to allow for air circulation.

3) An initial application of oil finish with UV inhibitors is a good way to help the wood adjust and minimize surface checking. After a year, you can continue sealing it every year (which helps to maintain its original color) or you can stop sealing it and let the deck weather to a natural silver color.